TGW Logistics receives major order from BSH Hausgeräte GmbH

The highly automated DC for spare parts marks the second joint project within months. A clad rack structure for the shuttle system will minimize space required.

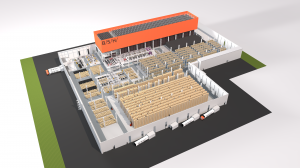

GRAND RAPIDS, MI, UNITED STATES, February 9, 2026 /EINPresswire.com/ -- TGW Logistics is delighted at BSH Hausgeräte GmbH's second order within just a few months. Following a project for the dishwasher manufacturer in the Bavarian town of Dillingen, a new shuttle warehouse with a clad rack structure will be completed in Nuremberg, Germany, by mid-2028. With this design, the rack structure also supports the building's wall and ceiling elements, making optimal use of the available space.

BSH Hausgeräte GmbH represents a portfolio of world-renowned home appliance brands, including Bosch, Siemens, Gaggenau and Neff. Their product range includes everything from stoves, ovens and kitchen hoods to dishwashers, washing machines, dryers, fridges and freezers, as well as small household appliances. Founded in 1967, the company employs roughly 57,000 people worldwide and generated a revenue of 15.3 billion euros in 2024.

SHUTTLE SYSTEM WITH CLAD RACK STRUCTURE

A spare parts logistics location is currently being built in Nuremberg for BSH Hausgeräte GmbH. The company opted for a shuttle warehouse with a clad rack structure as the fulfillment system; this means that the building's wall and ceiling elements will also be supported by the rack structure. This allows the available space to be used to the fullest. Technically speaking, the planning and realization of such a structure is an ambitious undertaking: the rack must withstand the force of wind and the weight of snow, and the connections between the wall and ceiling construction and to the floor slab are crucial to the overall stability of the system.

"This second joint project with BSH Hausgeräte GmbH within just a few months represents a great vote of confidence in our collaboration" stresses Martin Waldenberger, Chief Sales Officer of the Customer Unit Central Europe at TGW Logistics. “The clad rack shuttle warehouse constitutes a technically unique structure that very few companies are capable of implementing reliably. TGW Logistics has years of expertise and experience in planning and realization to fall back on.”

WERX SOFTWARE FOR PLANNING AND CONTROL

The core element of the TGW solution is a shuttle system with roughly 300,000 storage locations. Orders will be compiled at ergonomic PickCenter picking workstations; a network of about 1 mile of energy-efficient KingDrive conveyor technology will interconnect the various areas of the distribution center.

WERX, the TGW Warehouse Management Software, will handle planning, controlling, and monitoring of all shuttle and conveyor processes and will be connected to BSH Hausgeräte GmbH's SAP warehouse management software.

TGW Logistics

TGW Logistics

email us here

Visit us on social media:

LinkedIn

YouTube

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.